Die casting is a manufacturing process that has revolutionized the production of complex metal parts. Among the various metals used for die casting, A356 Aluminum Casting has emerged as a standout choice. Its unique combination of properties makes it ideal for creating intricately detailed and lightweight components. In this blog, we’ll take a closer look at die casting with aluminum and explore the reasons why it has become a cornerstone of modern manufacturing.

The Die Casting Process

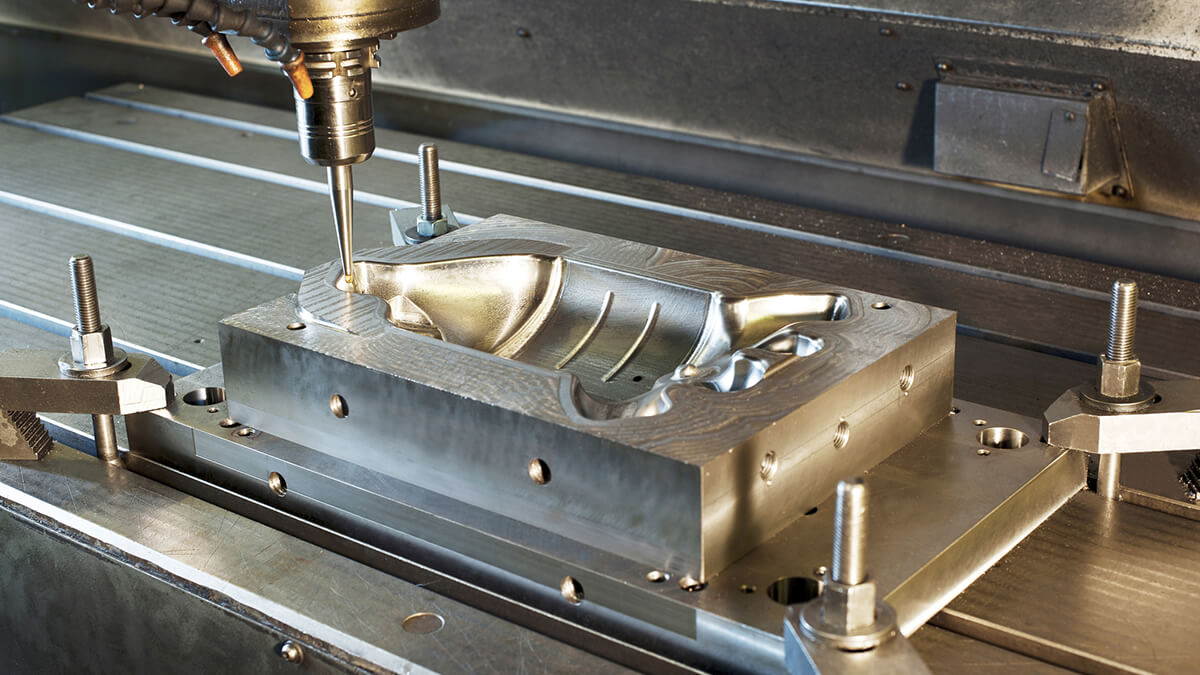

Before diving into the merits of aluminum die casting, let’s first understand the die casting process itself. Die casting is a method used to produce high-quality, consistent metal parts with tight tolerances. It involves forcing molten metal into a reusable mold, called a die, under high pressure. Once the metal solidifies, the die is opened, revealing the final part.

Die casting offers several key advantages:

- Complex Geometry: Die casting allows for the creation of intricate and complex parts with fine details, such as thin walls, sharp corners, and textured surfaces. This capability is especially valuable in industries like automotive, aerospace, and electronics, where intricate designs are the norm.

- High Production Speed: The process is exceptionally fast, with cycle times measured in seconds or minutes. This speed is essential for meeting the demands of mass production.

- High Precision: Die casting offers tight tolerances and dimensional stability, ensuring that each part produced is consistent and accurate.

Why Aluminum?

Aluminum die casting has gained popularity across various industries for several compelling reasons:

Lightweight Advantage

Aluminum is renowned for its low density, making it one of the lightest metals used in die casting. This attribute is particularly valuable in industries where weight reduction is a priority, such as automotive and aerospace. The lightweight nature of aluminum helps improve fuel efficiency in vehicles and enhances the overall performance of aircraft.

Superior Thermal Conductivity

Aluminum boasts excellent thermal conductivity properties. This makes it ideal for components that need to dissipate heat effectively, such as heat sinks in electronics or engine components in automotive applications. Its ability to rapidly conduct and dissipate heat helps prevent overheating and ensures the longevity of critical parts.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer on its surface, which makes it highly resistant to corrosion. This characteristic ensures that aluminum die-cast parts remain durable and reliable even in harsh environments, such as outdoor automotive components or marine applications.

Recyclability

Environmental considerations are increasingly important in modern manufacturing. Aluminum is not only highly recyclable but also retains its properties after recycling. This sustainability factor aligns with the growing emphasis on eco-friendly practices in the industry.

Cost-Efficiency

The cost-effectiveness of aluminum die casting is a significant driver of its popularity. The material is readily available and less expensive than some other die-casting metals, such as zinc or magnesium. Additionally, the speed of the die casting process itself contributes to cost savings in terms of labor and production time.

Applications of Aluminum Die Casting

Aluminum die casting finds its application across a wide spectrum of industries:

- Automotive: Engine components, transmission housings, and structural parts.

- Aerospace: Aircraft components, including structural parts, brackets, and engine components.

- Electronics: Heat sinks, electronic enclosures, and connectors.

- Consumer Goods: Household appliances, power tools, and lighting fixtures.

- Medical Devices: Equipment housings, instrument components, and brackets.

- Industrial Equipment: Machinery components, motor housings, and pump parts.

- Sporting Goods: Bicycle frames, golf club heads, and fishing reel bodies.

Conclusion

Aluminum die casting is a remarkable manufacturing process that has shaped modern industries by providing precision, versatility, and cost-efficiency. Its ability to create lightweight, intricate, and durable parts has solidified its position as a manufacturing powerhouse. As technology continues to advance, we can expect aluminum die casting to play an even more significant role in shaping the future of various industries, from transportation to electronics and beyond.